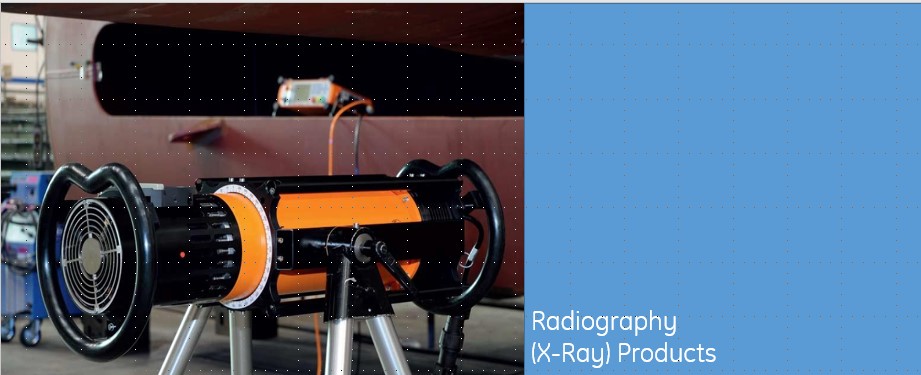

Radiography (X-ray) – Non-Destructive Testing

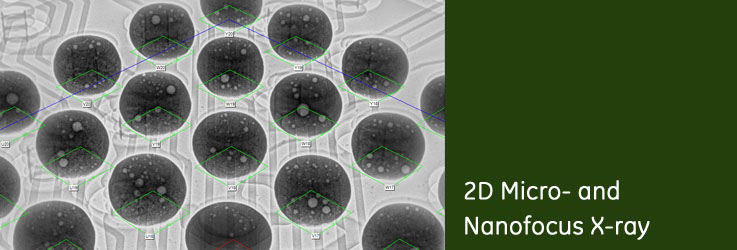

Radiography (X-ray) is a non-destructive testing (NDT) method that examines the volume of a specimen. Radiography (X-ray) uses X-rays and gamma-rays to produce a radiograph of a specimen, showing any changes in thickness, defects (internal and external), and assembly details to ensure optimum quality in your operation.

Waygate Technologies business offers a full range of Industrial radiographic equipment and techniques. We will work with you to identify the most appropriate solution to ensure optimum technique performance, speed and economy for your application. In addition to X-ray inspection systems, WT provides X-ray services on a fee basis.