Description

[vc_widget_sidebar sidebar_id=”mmpm_menu_widgets_area_1″]

Key Features and Benefits

- Compact, lightweight & rigid system

- Fast & easy setup of the system

- No belts, no straps, no spacers just clamp the scanner onto your specimen

- Miniature rolling encoder for accurate sizing & position recording

- No axial slippage

- Minimum maintenance

Applications

- Weld assessment from large diameter pipe to flat surface (3.5″)

- Corrosion assessment with single axis inspection

| Storage Temperature | -20…+70 °C |

| Operating Temperature | 0…+50 °C |

| Protection Rating | IP67 |

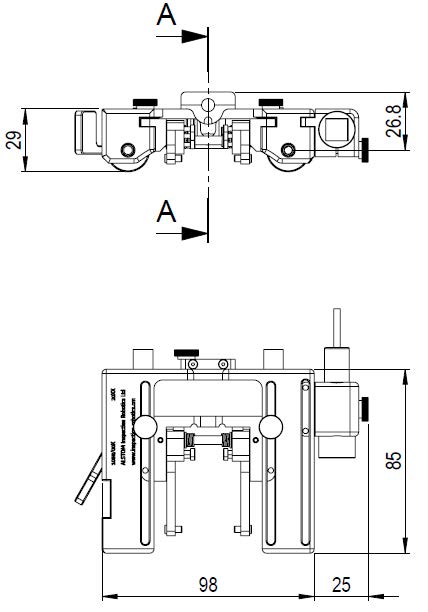

| Dimensions (L X B X H) | 98mm x 85mm x 29 mm (w/o laser) |

| Test Object Min. Ø (OD)

Outer Pipe Inspection |

90mm to flat |

| Test Object Min. Ø (ID)

Inner Pipe Inspection |

200mm to flat |

| Weight | 680g (w/o laser and probe) |

| Wedges Size | Max 40 x 70mm footprint

Width 23 to 40mm Further width upon request |

| Position Feedback | A/B encoder signal, 4.07 cts/mm |